Welcome to the Marine Air Systems Control Panel Manual․ This guide provides essential information for understanding, installing, and operating marine air systems effectively․ It covers system components, operational modes, and troubleshooting tips to ensure optimal performance and comfort․

Importance of the Control Panel in Marine Air Systems

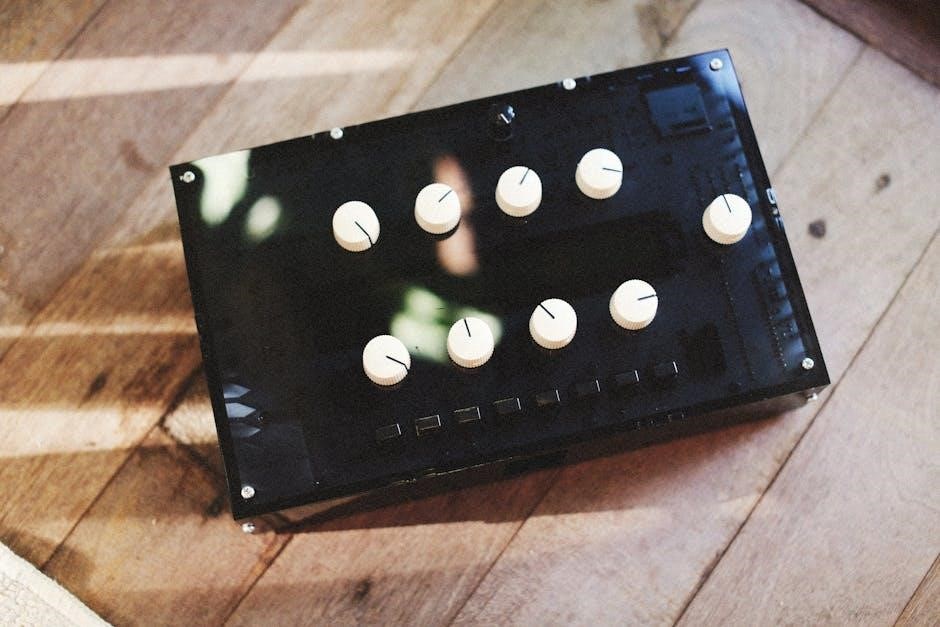

The control panel is the central interface for monitoring and managing marine air systems, ensuring optimal performance and comfort․ It integrates sensors, microcontrollers, and display panels to regulate temperature, humidity, and airflow․ By providing real-time data and operational controls, the panel allows users to adjust settings, diagnose issues, and maintain system efficiency․ Its role in diagnostics and troubleshooting is crucial, helping identify malfunctions such as power supply problems or sensor failures․ The control panel ensures reliable operation, energy efficiency, and consistent comfort in marine environments, making it an essential component of modern marine air systems․

Overview of the Manual Structure

This manual is organized into clear sections to guide users through the operation, installation, and maintenance of marine air systems․ It begins with an introduction to the control panel’s role and importance․ The manual then details system components, including hardware and software, followed by installation and setup guidelines․ Operating modes, such as cooling, heating, and automatic fan control, are explained in depth․ Troubleshooting sections address common issues like power supply and sensor malfunctions․ Finally, maintenance tips ensure system longevity․ Appendices provide additional resources, including wiring diagrams and technical specifications․ This structured approach ensures users can easily navigate and understand all aspects of marine air systems for optimal performance and reliability․

System Components and Features

The marine air systems feature advanced components, including sensors, microcontrollers, and display panels․ The system integrates hardware and software for precise temperature control and monitoring, ensuring optimal performance․

Hardware Components: Sensors, Microcontrollers, and Display Panels

The marine air systems rely on advanced hardware components to ensure precise control and monitoring․ Sensors are crucial for detecting temperature, humidity, and pressure levels, providing real-time data to the system․ Microcontrollers act as the brain, processing sensor inputs and executing commands to maintain optimal conditions․ Display panels offer user-friendly interfaces, showcasing system status, modes, and alerts․ These panels often feature touchscreens or push buttons for easy operation․ Together, these components form a robust framework that enables efficient climate control in marine environments․ Proper installation and maintenance of these hardware elements are essential for reliable performance and longevity of the system․

Software and Firmware Overview

The software and firmware are the backbone of marine air systems, enabling seamless control and monitoring․ The system operates on advanced firmware that manages cooling, heating, and automatic fan modes․ User-friendly software interfaces, accessed via display panels, allow for real-time adjustments and monitoring of temperature, humidity, and airflow․ Firmware updates ensure compatibility with evolving technologies and enhance system performance․ The software also supports diagnostic tools, alerting users to potential issues and guiding troubleshooting․ Integrated with hardware components, the firmware optimizes energy efficiency and ensures reliable operation in marine environments․ Regular updates and proper maintenance are essential to uphold system functionality and adapt to changing conditions at sea․

Installation and Setup Guidelines

Proper installation of marine air systems involves mounting the display panel correctly, following wiring diagrams, ensuring power supply, and adhering to safety guidelines for optimal functionality․

Mounting the Display Panel

The display panel should be mounted on an interior wall at a height slightly above the mid-point of the cabin for accurate temperature sensing․ Ensure it is positioned in an area with good air circulation, avoiding direct sunlight or moisture exposure․ The cutout size for the display panel must match the manufacturer’s specifications to ensure a proper fit․ Secure the panel firmly to prevent vibration or movement while the vessel is in operation․ Additionally, ensure the panel is at least 3 feet away from the air handler to maintain accurate temperature readings․ Proper sealing around the mounting area is crucial to prevent water ingress, especially in marine environments․ Follow the provided template or installation guide for precise measurements and alignment․

Wiring Diagrams and Electrical Connections

Refer to the wiring diagrams provided in this manual to ensure correct electrical connections for your marine air system․ Start by identifying the power supply requirements, typically 12V or 24V DC, depending on the system․ Connect the display panel to the control unit using the specified communication cables․ Ensure all sensors, such as temperature and humidity sensors, are properly linked to the control panel․ Verify that the circuit breaker for the air conditioning unit is switched on at the ship’s electrical panel․ Double-check all connections for tightness and insulation to prevent electrical faults․ If unsure, consult a certified marine electrician to avoid potential hazards․ Always disconnect the power supply before performing any maintenance or repairs․

Operating Modes and Controls

Marine air systems offer multiple operating modes, including cooling, heating, automatic fan, and moisture control․ These modes can be easily selected using the display panel’s push buttons․

Cooling Mode Operation

The cooling mode operates by activating the compressor and fan to lower the cabin temperature․ Select this mode on the display panel for optimal cooling․ The system uses a built-in air sensor to monitor and maintain the desired temperature․ Ensure proper installation of the display panel for accurate sensing․ Activate cooling by pressing the mode button until “Cooling” appears․ The thermostat will cycle the compressor on and off to maintain comfort․ For best performance, ensure uninterrupted power supply and proper ducting connections․ Refer to the troubleshooting section if issues arise during operation․

Heating Mode Operation

The heating mode provides warmth by engaging the reverse cycle operation․ Select this mode on the display panel during colder conditions․ The system activates the compressor and fan to circulate warm air․ The thermostat ensures the set temperature is maintained by cycling the compressor on and off․ For optimal performance, ensure the display panel is correctly installed in an area with good air circulation․ The Passport I/O system supports seamless transitions between cooling and heating modes․ Regularly check the power supply and duct connections to avoid interruptions․ If the system does not activate, refer to the troubleshooting section for common issues like power outages or sensor malfunctions․ Proper maintenance ensures reliable heating performance and energy efficiency․

Automatic Fan Mode and Moisture Control

The Automatic Fan Mode optimizes airflow by adjusting fan speed based on system demand, ensuring efficient cooling or heating․ This mode prevents excessive energy consumption while maintaining cabin comfort․ Moisture Control works alongside this mode to reduce humidity, preventing mold and mildew growth․ Sensors monitor air moisture levels, automatically adjusting the fan to maintain a dry environment․ For optimal performance, ensure the display panel is installed in an area with unrestricted airflow․ Regularly inspect and clean moisture sensors to ensure accuracy․ If moisture levels remain high, check the drainage system for blockages․ Proper use of these features enhances system efficiency and extends equipment lifespan while maintaining a comfortable marine environment․

Troubleshooting Common Issues

Identify and resolve issues like power outages, sensor faults, or fan malfunctions․ Check circuit breakers, wiring connections, and sensor accuracy․ Refer to specific troubleshooting sections for detailed guidance․

Diagnosing Power Supply Problems

Power supply issues are common and critical to address․ First, ensure the system is properly connected to a power source․ Check the circuit breaker or fuse box to confirm the circuit is not tripped or blown․ Verify the voltage matches the system’s requirements (115V or 230V)․ If the control panel does not light up, inspect wiring connections for damage or corrosion․Consult the wiring diagram in the manual to ensure all connections are correct․ Use a multimeter to test voltage at key points․ If issues persist, contact a certified technician or the manufacturer’s support team for assistance․ Regular maintenance can prevent such problems․

Resolving Fan and Sensor Malfunctions

Fan and sensor malfunctions can disrupt system performance․ Start by checking the fan for blockages or debris․ Ensure it spins freely and replace it if damaged․ For sensors, verify proper installation and location․ An incorrectly placed sensor may fail to detect accurate temperatures․ Use a multimeter to test sensor resistance and ensure it matches specifications․ If a sensor is faulty, replace it with an OEM-compatible part․ Reset the system after repairs and monitor operation․ Regular cleaning and inspection of fans and sensors can prevent issues․ Always refer to the wiring diagram for troubleshooting connections․ Addressing these malfunctions promptly ensures efficient system operation and maintains cabin comfort․

Maintenance and Support

Regular maintenance ensures optimal performance․ Check sensors, clean fans, and inspect wiring․ Refer to contact customer support for repairs or manual clarifications․

Routine Maintenance Tips

Regular maintenance is crucial for ensuring the longevity and efficiency of marine air systems․ Start by cleaning the display panel and sensors to ensure accurate temperature readings․ Check all wiring connections for signs of wear or corrosion, and tighten any loose connections․ Inspect the fans and vents for dust or debris, as blockages can reduce airflow and system performance․ Additionally, verify that the power supply is stable and meets the system’s voltage requirements․ Schedule annual professional inspections to address any potential issues before they escalate․ By following these routine maintenance tips, you can maintain optimal system operation and prevent unexpected malfunctions․

Leave a Reply

You must be logged in to post a comment.